When we took Ermy apart we labelled a lot of things. Most of the electrical connectors, some of the bolts… but none of the vacuum system. In particular, none of the solenoids which actually control those systems. A lot of diagrams exist for this, but, none of the parts are very clearly marked, they have no part numbers or were close enough on these diagrams to be confusing. Or in our case we had taken them all off and didn’t know which of the solenoids was which.

So here is what we learnt when we put it all back together.

Vacuum is generated by the inlet manifold. When the throttle body is closed, the engine is actively pulling in more air than there is in the manifold, resulting in a vacuum. Any vacuum systems on the MK2 are thus driven off of the inlet manifold. But these systems don’t want vacuum all of the time. As a result there are a series of solenoids which turn the vacuum on and off when it’s not wanted.

There are 4 systems on the Inlet Manifold which require vacuum in some way:

- Brake Servo

- Fuel Pressure Regulation

- Charcoal Canister recirculation system.

- VICS/Butteryfly system

Braking

The easiest and simplest of these to find is the brake servo, fed by a thick pipe out of the top back of the manifold. This is the easiest to find because the hoses naturally and obviously fit in the right places, even after you take the car apart. The application of vacuum here makes the brakes more effective, and since you tend to get off the throttle when you brake, there is more vacuum available, assisting the braking even more.

Fuel

Fuel pressure regulation is obviously important. This system works by applying vacuum to the fuel flow, restricting the flow of fuel when there is a greater vacuum, which occurs when the car is idle. When there is no vacuum (I.e. when accelerating), there is no restriction and get more fuel to the fuel rail.

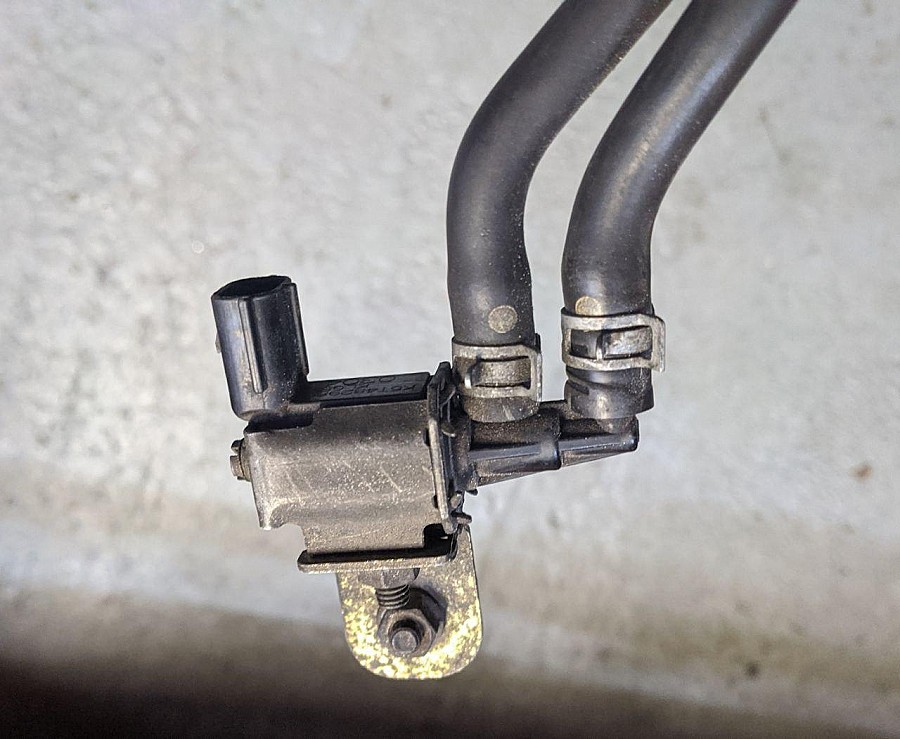

You can identify the fuel pressure solenoid as it has a black cap on top, and the vacuum hoses at the top and bottom of the unit. This solenoid is usually housed on a little bracket at the back left of the engine bay, along with the Charcoal Canister solenoid.

Charcoal Canister

The Charcoal Canister was originally designed to meet California emissions regulations, allowing fuel vapours from the tank to be moved to the engine bay and be burned off, along with the EGR system fumes.

The canister delete is a common change, for weight saving and engine bay tidiness on regular cars but particularly on kit cars as it saves running a hose all the way from the back of the vehicle.

This solenoid is attached to the same bracket as the fuel pressure solenoid and has two hose connectors at the bottom.

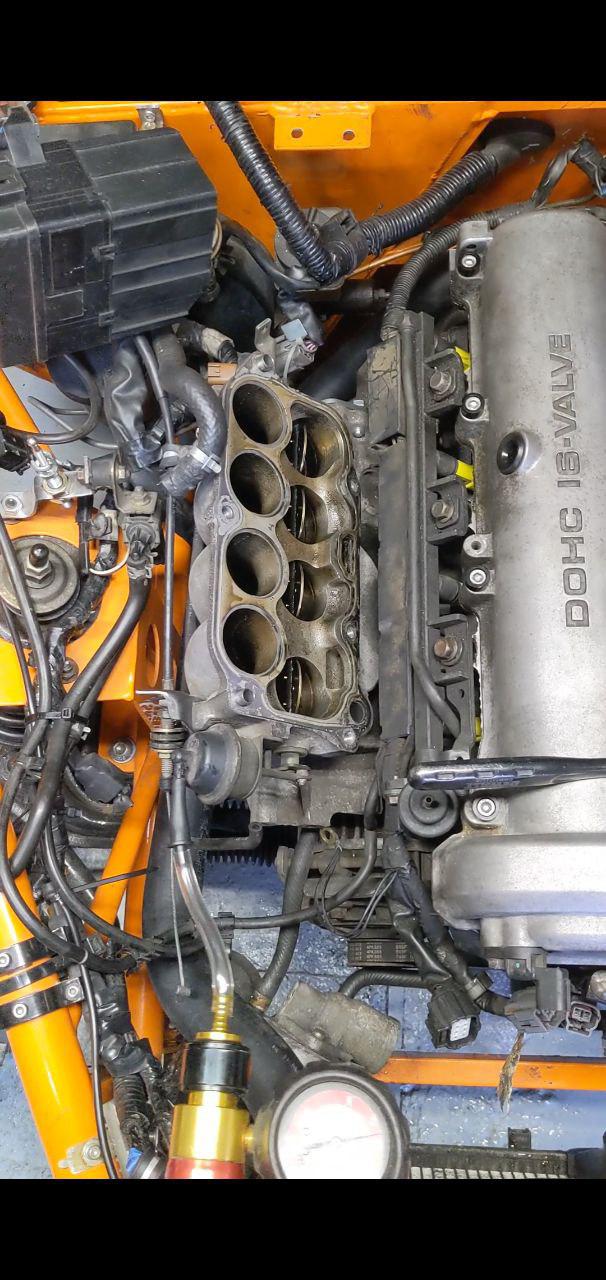

VICS

VICS stands for Variable Inertia Charging System. Its a set of butterfly valves inside of the manifold which open up when the engine his 5200 rpm.

There are diagrams of how this works, from the original Mazda manuals:

As you can see, the opening of the valves does not allow more air into the system, it simply adjust the flow of air before it enters the engine.

The VICS Solenoid is attached to the back of the engine and has a brown electrical connector, with both the vacuum inlets and outlets at the bottom. This connects to the small “spaceship” connector to the right of the throttle body.

The Connections

Knowing all of the above now makes the following 90’s spec diagram make a lot more sense.

And this made it even more impressive that we connected the VICS connector to the wrong place and left the EGR/Canister solenoid connected. In theory this will only have had an impact when the engine would have been over 5200 rpm.